Our Portfolio

At Taurus Biogas, we don’t just manage biogas facilities – we optimize them for peak performance, maximizing value for our partners.

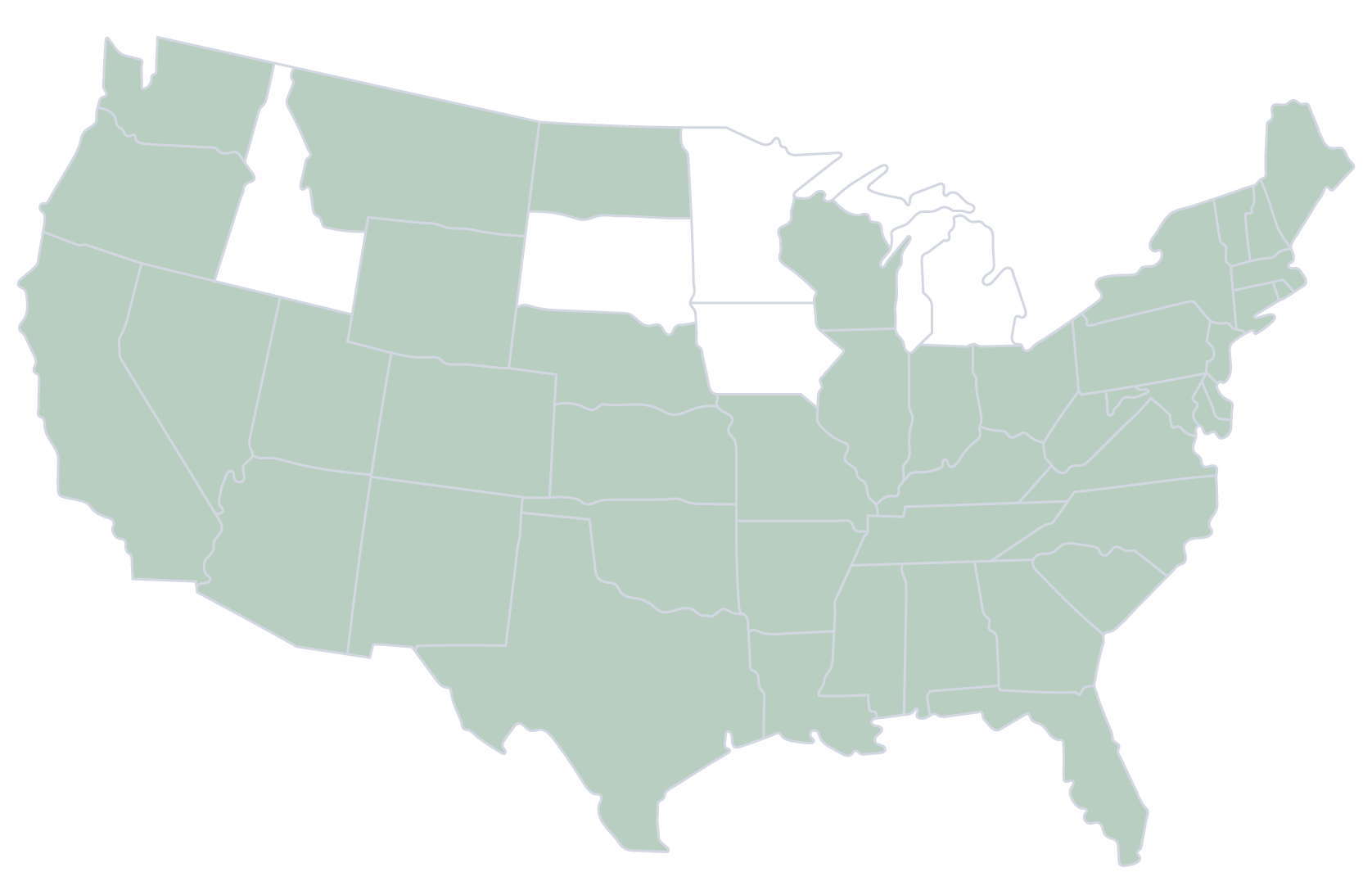

With nine RNG facilities across five U.S. states, our proven track record demonstrates our ability to drive measurable operational excellence and deliver reliable, impactful results for our partners.

De Saegher Energy RNG Facility

Location: Middleton, MI

Feedstock: 100% Dairy Manure

RNG Production: 200,000 MMBtu/yr

(currently expanding to double capacity)

Commercial Operations: Q3-2023

Our Role: Complete O&M Services

The Challenge

This facility in Central Michigan utilizes manure from the De Saegher Dairy and the Milk Star Dairy. It features shared infrastructure at the De Saegher Dairy for manure thickening, anaerobic digestion, biogas conditioning, and pipeline interconnection.

Our Solution

Taurus Biogas provides complete O&M Services. Commissioning of the facility commenced in Q1-2023, and the first gas injection occurred in Q3-2023.

The manure collection and pretreatment processes include flush flumes, sand separation barns, piston pumps, cross-auger channels, sand manure separators, and hydro-cyclones. The thickening system consists of two tanks and four rotary drum clarifiers.

The facility employs two anaerobic digester tanks with jet mix systems and a covered lagoon for additional biogas collection.

The membrane-based gas upgrading system includes a blending skid and equipment for hydrogen sulfide and moisture removal.

The Results

The facility was operating at full capacity and undergoing an expansion to double its processing and production capabilities. Taurus Biogas is responsible for the complete O&M services for this operational facility.

East Valley Development RNG Facility

Location: Declo, ID

Feedstock: 100% Dairy Manure

Estimated RNG Production: 464,000 MMBtu/yr

Estimated Commercial Operations: Q4-2025

Our Role: Complete O&M Services

The Challenge

This project, located near Declo, Idaho, processes manure from the Idaho Jersey Girls dairy. The manure is received in the form of flushed and vacuum collected streams.

Our Solution

Taurus Biogas provides complete O&M services for this facility. This includes managing the process where manure is screened, thickened, and digested to generate raw biogas, which is then upgraded and injected into a pipeline lateral.

The facility employs inclined screws and sand lanes for initial sand removal. Rotary drum separators are used to concentrate the coarser solids and fiber. Gravity thickeners further separate the remaining fine solids.

The anaerobic digestion occurs in six 3-million-gallon digesters. These digesters are mesophilic, continuously stirred tank reactors (CSTR) with mixing via hydraulic nozzle systems.

The raw biogas undergoes processing through an amine gas upgrading system.

Taurus Biogas also manages the digestate processing, utilizing screw presses to recover fibers for bedding and centrifuges to remove additional solids.

The Results

Initial phases of the facility began operating in 2023, with full commercial operations targeted for Q4-2025. Taurus Biogas delivers comprehensive O&M services for this project.

WMR RNG Facility

Location: St Louis, MI

Feedstock: 100% Dairy Manure

Estimated RNG Production: 284,000 MMBtu/yr

Estimated Commercial Operations: Q3-2025

Our Role: Complete O&M Services

The Challenge

This facility in Central Michigan utilizes manure from the Wheeler, Mibelloon, and Redstone dairies. Infrastructure at the Mibelloon Dairy and Wheeler Dairy sites is in place for manure thickening, anaerobic digestion, biogas conditioning, and pipeline interconnection.

Our Solution

Taurus Biogas provides complete O&M Services. Commissioning of the facility commenced in Q1-2025, and the first gas injection is scheduled to occur in Q3-2025.

The Results

Taurus Biogas is responsible for the complete O&M services for this facility, which is operating at full capacity and undergoing an expansion to double its processing and production capabilities.

Spring Creek RNG Facility

Location: Battle Creek, MI

Feedstock: 100% Dairy Manure

Estimated RNG Production: 95,000 MMBtu/yr

Estimated Commercial Operations: Q4-2025

Our Role: Complete O&M Services

The Challenge

This facility in Southwestern Michigan utilizes manure from the Spring Creek and Bear Lake dairies. The facility includes infrastructure for manure thickening, anaerobic digestion, biogas conditioning, and a pipeline interconnection.

Our Solution

Taurus Biogas provides complete O&M Services. Commissioning of the facility is expected to commence in Q3-2025, and the first gas injection is scheduled to occur in Q4-2025.

Ash Grove RNG Facility

Location: Lake Benton, MN

Feedstock: 100% Dairy Manure

Estimated RNG Production: 57,500 MMBtu/yr

Estimated Commercial Operations: Q3-2023

Our Role: Complete O&M Services

The Challenge

This facility utilizes manure from the Ash Grove Dairy. The facility includes Infrastructure for anaerobic digestion, biogas conditioning, and a virtual pipeline interconnection.

Our Solution

Taurus Biogas began providing complete O&M Services in Q2-2025.

Drumgoon RNG Facility

Location: Lake Norden, SD

Feedstock: 100% Dairy Manure

Estimated RNG Production: 138,000 MMBtu/yr

Estimated Commercial Operations: Q3-2023

Our Role: Complete O&M Services

(Photo courtesy of Business Wire)

The Challenge

This facility utilizes manure from the Drumgoon Dairy. The facility includes Infrastructure for manure thickening, anaerobic digestion, biogas conditioning, and a virtual pipeline interconnection.

Our Solution

Taurus Biogas began providing complete O&M Services in Q2-2025.

Marshall Ridge RNG Facility

Location: State Center, IA

Feedstock: 100% Dairy Manure

Estimated RNG Production: 240,000 MMBtu/yr

Estimated Commercial Operations: Q4-2023

Our Role: Complete O&M Services

The Challenge

This facility utilizes manure from the Marshall Ridge Dairy. The facility includes Infrastructure for manure thickening, anaerobic digestion, biogas conditioning, and a pipeline interconnection.

Our Solution

Taurus Biogas began providing complete O&M Services in Q2-2025.

Tri-Cross RNG Facility

Location: Viborg, SD

Feedstock: 100% Dairy Manure

Estimated RNG Production: 130,000 MMBtu/yr

Estimated Commercial Operations: Q4-2023

Our Role: Complete O&M Services

The Challenge

This facility utilizes manure from the Tri-Cross Dairy. The facility includes Infrastructure for manure thickening, anaerobic digestion, biogas conditioning, and a virtual pipeline interconnection.

Our Solution

Taurus Biogas began providing complete O&M Services in Q2-2025.

VF Renewable RNG Facility

Location: Revillo, SD

Feedstock: 100% Dairy Manure

Estimated RNG Production: 117,300 MMBtu/yr

Estimated Commercial Operations: Q4-2024

Our Role: Complete O&M Services

The Challenge

This facility utilizes manure from the Victory Farms dairy. The facility includes Infrastructure for manure thickening, anaerobic digestion, biogas conditioning, and a virtual pipeline interconnection.

Our Solution

Taurus Biogas began providing complete O&M Services in Q2-2025.

Delivering Tangible Value to Your Biogas Venture

Partnering with Taurus Biogas translates to significant advantages:

Reduced Downtime

Proactive maintenance programs minimize disruptions, keeping your facility running smoothly.

Increased Profitability

Our expertise optimizes operations, leading to higher output and lower costs.

Safety First

Industry-leading safety protocols protect your investment and your people.

Seamless Integration

We integrate our services with your day-to-day operations, ensuring minimal disruption.

Effective Feedstock Management

We maximize methane production through optimized feedstock handling and processing.

High-Quality Byproducts

Our expertise ensures valuable byproduct generation, enhancing on-site utilization or off-site monetization.

Regulatory Compliance

We handle the complexities of environmental regulations, allowing you to focus on growth.

Reduced Downtime

Proactive maintenance programs minimize disruptions, keeping your facility running smoothly.

Increased Profitability

Our expertise optimizes operations, leading to higher output and lower costs.

Safety First

Industry-leading safety protocols protect your investment and your people.

Seamless Integration

We integrate our services with your day-to-day operations, ensuring minimal disruption.

Effective Feedstock Management

We maximize methane production through optimized feedstock handling and processing.

High-Quality Byproducts

Our expertise ensures valuable byproduct generation, enhancing on-site utilization or off-site monetization.

Regulatory Compliance

We handle the complexities of environmental regulations, allowing you to focus on growth.